Services

Our expertise extends from laboratory testing to product registration to help you face the challenges ahead confidently.

The Medical Devices Directive established in the EU states that medical devices (including disinfectants and antiseptics) must be manufactured through verifiable processes that present no risk to users. In order to prove a disinfectant or medical device as compliant with the Directive, it is assessed to meet high safety, health and environmental protection requirements before it is declared fit for the European market. At Viroxy, we indirectly help manufacturers adhere to these high standards by conducting microbiological tests at an affordable rate. We can also facilitate the process of placing your medical device in the European market with our expertise so that it is seamless and quick without posing risks to the well-being of the community.

Disinfectant Efficacy Testing

We conduct disinfectant efficacy testing for surface disinfectants, high-level disinfectants, instrument disinfectants and hand hygiene products according to European Norms and other international standards to ensure all efficacy claims are substantiated. At present, our disinfectant efficacy tests are focused on the medical sector, food, industrial, domestic & institutional sector, and veterinary sector.

Read more about Disinfectant Efficacy Testing

Yeasticidal and Fungicidal Tests

Bioburden Testing

Non-sterile medical devices are expected to contain some level of bioburden. However, these must be of non-objectionable microorganisms and they must be contained within appropriate ranges to prevent the devices from causing disease outbreaks. At Viroxy, we use proven methods in bioburden testing to reveal the type and quantity of viable microorganisms on a medical device or its components to determine if the product is safe for use.

Biocompatibility Testing

ISO 10993 is a comprehensive standard that governs the biocompatibility testing of medical devices. It ensures that medical products do not cause adverse effects when they come into contact with the body. The standard includes various tests to assess the biological response to materials, covering aspects such as cytotoxicity, sensitization, irritation, and systemic toxicity. Compliance with ISO 10993 is crucial for manufacturers to ensure the safety and efficacy of their medical devices, ultimately protecting patient health and meeting regulatory requirements.

Material Compatibility Testing

Material compatibility testing is a critical standard in the dental industry, ensuring the compatibility of materials used in dental restorations and prosthetics. It provides guidelines for evaluating chemical interactions between materials to ensure they work harmoniously together without compromising performance or patient safety. By adhering to these guidelines, manufacturers and dental professionals can guarantee the reliability and safety of dental products, leading to better patient outcomes and adherence to regulatory standards.

Chemical Analysis Testing

Chemical analysis is a scientific process used to identify the chemical composition and quantify the components of a substance or mixture. This discipline is critical in various fields, including pharmaceuticals, environmental science, food safety, and manufacturing, as it ensures compliance with quality standards and regulations. The principle of chemical analysis involves using techniques such as chromatography, spectroscopy, and titration to analyze materials at the molecular level. Its importance lies in its ability to provide accurate data essential for research, development, and quality control, ensuring that products meet safety and efficacy standards.

Sterility Testing

Manufacturers of sterile medical devices are required to prove the sterility of their production lots during the validation process. Sterility testing is a methodical process that must be undertaken carefully to avoid introducing external contaminant to a sample. Our microbiologists are well trained in the protocols of sterility testing and we can lend you a helping hand.

Environmental Monitoring Service

Ultimately, our concern is for the global community and the community we live in. Our environmental monitoring service helps operators of hotels, schools, cruise ships, restaurants, fitness centres, aged care facilities, kindergartens, nurseries and other facilities frequented by many, improve and maintain the surface and air quality of their premises.

Read more about Environmental Monitoring Service

Surface Monitoring with Contact Plates

Surface Monitoring with Swab Method

Product Registration & Consultation

Although validation of claims through laboratory analysis can be a time-consuming process, the challenge sometimes lies in getting products registered in other countries. And sometimes, it lies in understanding the general requirements of manufacturing disinfectants. Our regulatory officers have in-depth knowledge in international medical devices registration and can provide advisory services when required. With us, you will not only get microbiological laboratory services but also invaluable expert opinion when it is time to place your product in the market.

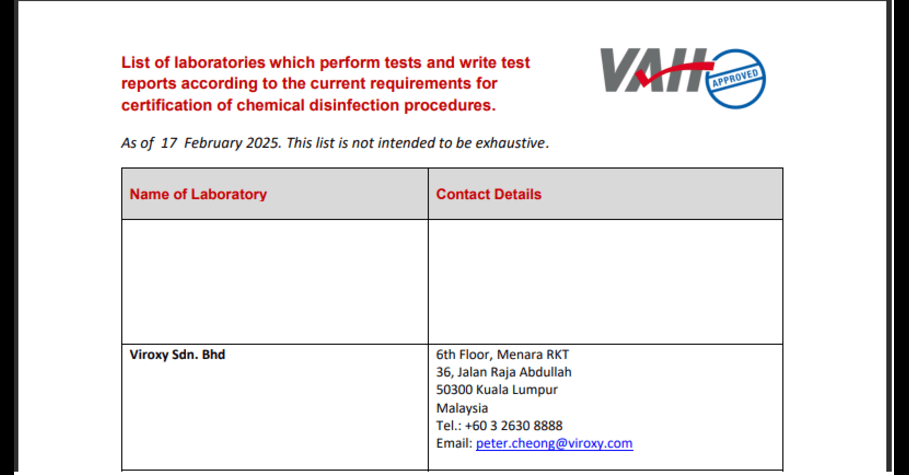

Verbund für Angewandte Hygiene (VAH)

VAH stands for Verbund für Angewandte Hygiene, or Association for Applied Hygiene in Germany. It is a highly respected organization that develops and maintains standardized procedures for testing the efficacy of disinfectants, primarily in Europe.

VAH provides a list of tested and certified disinfectants that meet strict efficacy criteria. It ensures products meet high scientific and practical standards through:

- Standardized testing protocols

- Independent evaluation by accredited laboratories

- Continuous review and updates based on the latest scientific evidence